Abstract

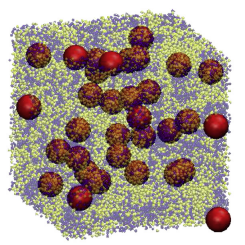

End-grafting polymer chains to nanoparticles in polymer nanocomposite is a widely used method to disperse inorganic particles in a polymeric matrix in order to improve the material properties. While many fundamental studies have investigated how various factors influence the dispersion or aggregation of the nanoparticles, the effect of grafting on the resulting material properties has received considerably less attention. In particular, the effect of nanoparticle curvature and grafting density on the mechanical properties in polymer nanocomposites remains elusive. In this study, we develop a coarse-grained model of a polymer glass containing grafted nanoparticles and examine the resulting effects on the mechanical properties. By carefully designing the parameters of our polymer nanocomposites model, we can maintain dispersion of the nanoparticles whether they are grafted with polymer chains or not, which allows us to isolate the effect of end-grafting on the resulting mechanical properties. We examine how the nanoparticle size and grafting density affect the elastic constants, strain hardening modulus, as well as the mobility of the polymer segments during deformation. We find that the elastic constants and yield properties are enhanced nearly uniformly for all of our nanocomposite systems, while the strain hardening modulus depends weakly on the grafting density and the nanoparticle size.