Abstract

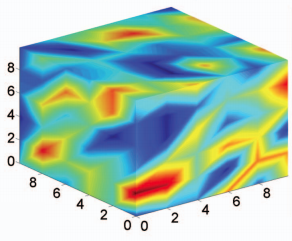

A polymer-diluent model exhibiting antiplasticization has been developed and characterized by molecular dynamics simulations. Antiplasticizer molecules are shown to decrease the glass transition temperature Tg but to increase the elastic moduli of the polymeric material in the low-temperature glass state. Moreover, the addition of antiplasticizing particles renders the polymer melt a stronger glass-forming material as determined by changes in the characteristic temperatures of glass formation, the fragility parameter D from fits to the Vogel-Folcher-Tamman-Hesse equation, and through the observation of the temperature dependence of the size of cooperatively rearranging regions (strings) in each system. The length of the strings exhibits a weaker temperature dependence in the antiplasticized glass-forming system than in the more fragile pure polymer, consistent with the Adam-Gibbs model of glass formation. Unexpectedly, the strings become increasingly concentrated in the antiplasticizer particles upon cooling. Finally, we discuss several structural indicators of cooperative dynamics, and find that the dynamic propensity (local Debye-Waller factor ⟨u2⟩p) does seem to provide a strong correlation with local molecular displacements at long times. The authors also consider maps of the propensity, and find that the antiplasticized system exhibits larger fluctuations over smaller length scales compared to the pure polymer.