Abstract

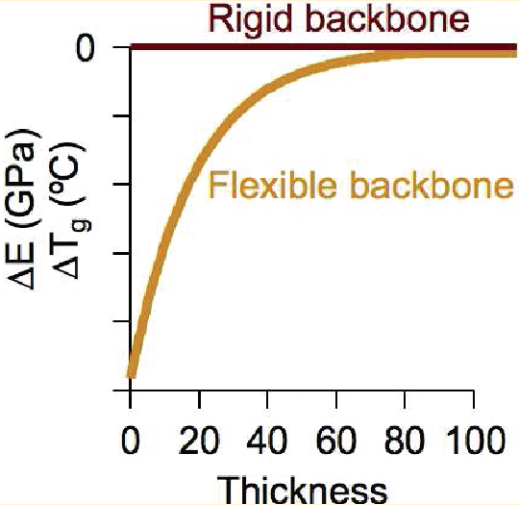

The effect of main chain stiffness and side chain flexibility on the elastic modulus and glass transition temperature (Tg) of thin polymer films is investigated using nontraditional polymers formed from 5-(2-phenylethylnorbornene). Depending on the polymerization route chosen, the resulting polymer backbone is comprised of either bicyclic (norbornyl) units, which leads to a relatively rigid polymer with a high bulk Tg, or monocyclic (cyclopentyl) units, which leads to a more flexible structure with a lower bulk Tg. The modulus and Tg of the rigid bicyclic polymer are thickness independent down to <10 nm, whereas the modulus of the more flexible monocyclic polymer decreases with decreasing thickness. By hydrogenation of the pendant phenyl ring to the cyclohexyl counterpart, we illustrate that minor changes in the relative flexibility of the side chain do not impact the observed thin film behavior. To further support our hypothesis that main chain stiffness (persistence length) plays a central role in confinement-induced changes in physical properties, a series of arylate/phosphonate copolymers, where the addition of phosphonate groups decreases the overall stiffness of the polymer backbone, are also examined. Similar to the polynorbornenes, the poly(arylate-co-phosphonate) polymers exhibit more pronounced thickness-dependent properties as the stiffness of the backbone decreases. We believe based upon our results that examination of chain flexibility in the thin film glass community for future works would be extremely useful in elucidating the physical origins of observed phenomena.